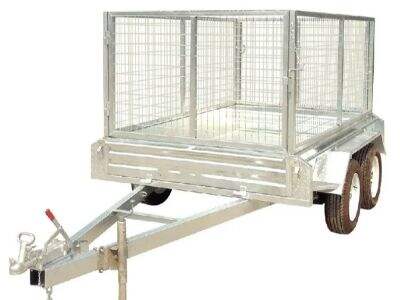

Do you ever wonder how the huge trailers we see on roads are so perfectly built? A particular kind of trailer is a tandem tipper trailers by Sweet Metal Products. These Tandem Trailer are not only fun to make, but pretty tough as well. Changing a lens is also go to be much more difficult though needlessly skillful and painstaking work. The process includes design, fabrication (welding), and painting. All of these steps require specific skills and focus on quality to get everything right.

Making Tandem Tipper Trailers

But a tandem tipper trailer is not just to put together some metal pieces. It'll make sure the trailer meet all needs perfectly as how would you know what to build if not. First, they have a detailed blueprint called the design plan and another component which is premium quality materials that are long-lasting yet sturdy. After they are plotted, the maintaining is performed by making use of welding (a method to become a member of metallic parts through melting) carefully.

Learning to Build Trailers

One has to go through various stages of training in order to become a professional builder of tandem tipper trailers. Builders often start by entering a trade school and learning metalwork as well as welding, while gaining hands on experience. For their first job, after they have been trained in the basics and are subsequently pinned with a tag (basic all- yield or advanced), they typically work alongside an experienced welder. They explain that the more challenging elements in building trailers can't be replicated without an apprenticeship such as this one.

They get some background, and then they enter the training center to learn how to design these large heavy-duty trailers weld them paint them utilize all of the fabrics before forged in this circuit. The importance of this extra schooling is paramount when it comes to being successful and proficient in the field.

The Hard Work of Builders

These quality tandem tipper trailers take a lot of time and effort to build. Builders need patience, focus and be extremely detail oriented. They spend all that hard work on the trailer, they better make darned sure it is safe and well-built. That means going over all-important details to make sure you did not miss anything.

You will get a long aged product from the trailer maker Therefore, they have no choice but to adhere into strict standards and that would mean not being able to skip stages. Each component of the trailer has to be adeptly operated so that it provides comfort and safety for whomever uses it.

Steps in Making Trailers

There are some important steps, which make tandem tipper trailers; the step-by-step process is given below. Every step becomes important in the formation of unyielding and reliable heavy-duty trailers. The builder starts by building the tandem tipper trailer based on what you require as a customer. Thus, there are no standardized solution. They consider the capacity of the trailer—its dimensions, weight and carrying capabilities. It is one of the most significant phases in planning, to ensure that once build time comes around it will achieve all necessary utilities for this client.

After an architect drafts the blueprint, a builder makes their mold for what materials to use. They choose metallic instruments and alternatives that may endure the load of holding a trailer collectively. This is when we think about what the system does, top level requirements (how far must it be able to tip) and begin selecting components from every part of the trailer that are going group into this solution to make sure they will work together on race day.

Then the actual building is started when it all ready. There are metal pieces that I measure accurately, cut to size and weld together. Every single weld is intensely checked out for durability, and carrier lifetime extending issues down the road.

Last, after the trailer is ready it gets painted and finished. After being inspected by the builder, and getting that stamp of approval on the trailer means its time to deliver it back to a happy customer.